News by TEWS

Press Releases, News and Upcoming Events.

TEWS Joins Bioenergy Europe: A New Opportunity in Moisture Measurement in the Biomass Industry

TEWS at the 14th World Meeting on Pharmaceutics: New Insights for New Business Opportunities

Enhancing Tobacco Industry Efficiency with TEWS Moisture Measurement Systems

Crafting the Future of Gelatin with Precision Drying - Ventilex & TEWS

Advanced Moisture Measurement Technology for Optimal Control in the Food Industry

Self-Ignition Risks in Hop, Alfalfa, Straw, and Hay Bales

Unlocking Excellence: The Future of Snus Quality is Here!

A Chinese plasterboard company customer satisfaction survey

Saving energy during the drying process: Benefits of TEWS sensors in Paper Industry

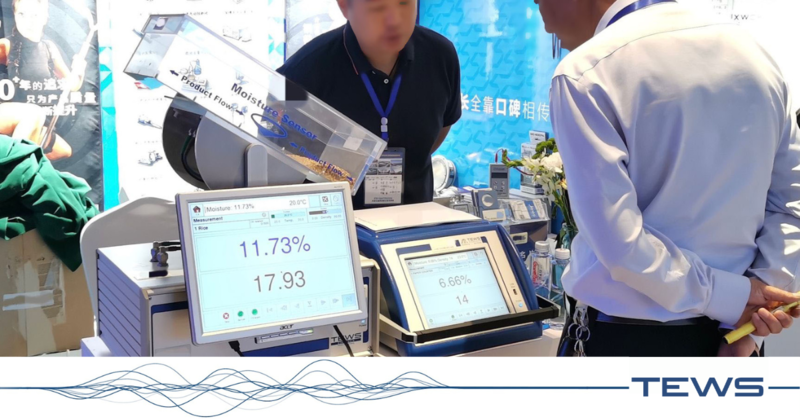

Quarantine in China? Not for TEWS instruments

Saving energy during the drying process: Benefits of TEWS sensors in Food Industry.

Saving energy during the drying process: Fluid bed dryer use-case in the Pharma Industry.

How to save energy during the drying process with TEWS

The innovative generation of product-setup-tool for the measurement system

How to save energy with TEWS-Technology?

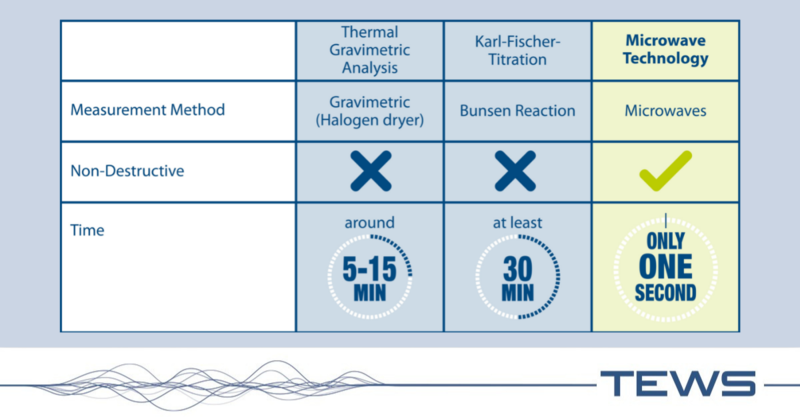

Microwave technology vs. KFT - which of the two is the more efficient technology?

MW 3012: The solution for your Weight Control System on the cigarette maker and filter maker.

How innovation drives performance development of our equipment

How our instruments can measure different tobacco blends, independent from its characteristics

How our Microwave Technology can Measure Moisture in Frozen Pasta

Measurement Moisture Increases Control.

TEWS & Bühlers MoisturePro Moisture Control

How to Visualize the Position and Amount of "Invisible" Glue on LIP-Paper

TEWS Technology Integrated Into Any Existing Filter Maker to Produce Highest Quality Capsule Filters for Cigarettes

Work Smarter With the HoloLens2 – Now Available for Rent or Purchase

An Innovative and Unique Approach to Measure the Moisture of Hair Switches

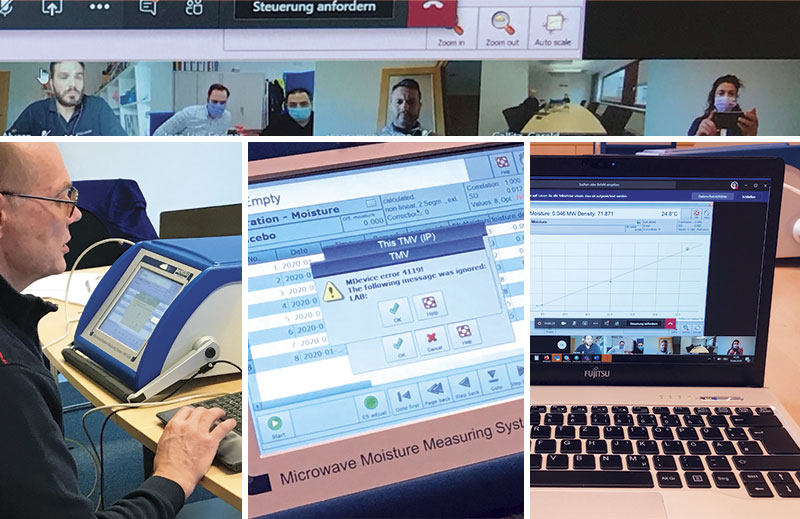

Remote Commissioning Free of Charge during Covid-19

TEWS of America strengthened its team

We are still standing!

KAM is KEY.

Co-Improving™ is our idea of Consulting & Customer Driven Solutions

Kohler Coating Inc. and TEWS announce joint development

Operational excellence in plasterboard production

The way to perfect flatness.

Tews Backs New System.

How to Control the Density of Fish Feed.

Innovative Microwave System for Moisture Measurement.

Accurate to the point - microwave-based moisture measurement increases productivity.

Contact

Feel Free to Contact Us.

TEWS Elektronik GmbH & Co. KG

Sperberhorst 10

22459 Hamburg

E-Mail: info@tewsworks.com

Phone: +49 40 555 911-0

Fax: +49 40 555 911-99