Solutions

tailormade for you

Experience

years

Development Time

months

Solutions that help companies to achieve their goals faster. For over 30 years TEWS moisture & density measurement solutions have been worldwide in all kinds of industries. Our high-performance solutions combine surface and core moisture detection as well as the measurement of density, weight and related parameters based on patented TEWS microwave technique.

Measurably better - No matter whether high-speed online weight control, moisture measurement, sorting, dryer control, coating or dosing, our high-performance solutions are simple: we provide patented microwave technique tied to passion driven services. Why? The answer is as simple as our solutions: to improve the production process of our clients. Or, in other words: to help our clients to achieve better results.

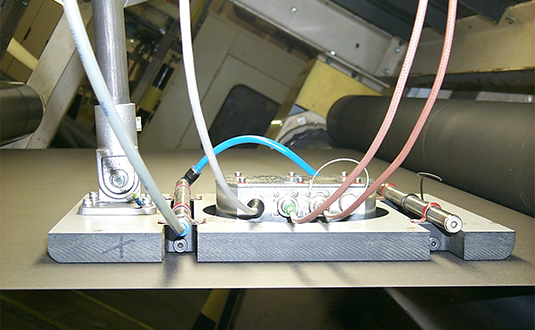

Our solutions have been developed and designed together with leading companies in several industries for high flexibility worldwide. Our engineers are not just able to adapt our technology to your processes, machines and applications, but also to turn new ideas into new solutions. That’s what we call: Co-Improving®.

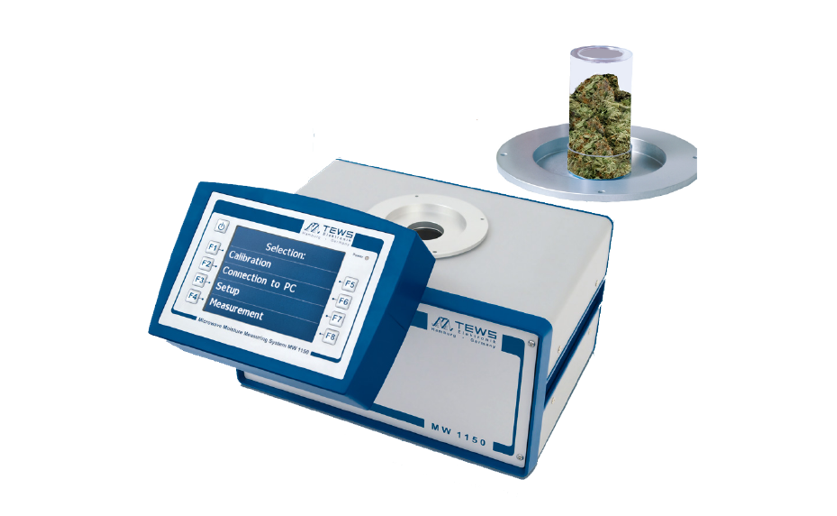

The TEWS method enables companies to gain high accurate data about the level of moisture content and density of their products. It’s a one-stop-shop without any sample preparation to optimize the whole production process in terms of cost savings and quality control.

Water Matters.

Product quality and efficiency can be significantly optimized by controlling the moisture content in almost all process steps. Managing the moisture of products is a key factor to achieve better results. TEWS patented solutions deliver high precision results. It's what matters when it comes to company goals and how to achieve them faster.

- Securing High-Speed-Production – Modern high-speed machines are fragile in a sense that minor deviations from the specified inflow or any piling-up within the production flow leads to severe interruptions. With up to 40,000 measurements per second we are well ahead of all production processes.

- Plant Efficiency – With our measurement results, machine builders can utilize their advanced machines at an optimum and reduce downtimes and waste to a minimum.

- Product Quality and Product Safety – A precise moisture level is decisive for the quality. In the industry a wrong moisture level can even harm the product safety as active ingredients may change and turn into toxic or higher the level of explosions if product becomes to dry and dusty.

- Storage Efficiency – Precise compliance with the recommended water content of components secures product integrity.

It Takes Two.

TEWS patented two-parameter measurement solutions enable companies to work with high precise data in both ways at the same time. Data that relate to the moisture content of products as well as their density. With more than one microwave even multiple content variations can be measured. This leads to even better results in terms of product quality and -efficiency.

- Mass Flow and Balance Check – Accurate density information being used to assure constant filling levels, content control.

- Quality Control and Product Safety – perfect final products due to full 100% online production control.

- Plant Efficiency – Self-adjusting machines based on sensor-controlled and algorithm-optimized production.

Areas of Application.

In all industries that currently do not use traditional methods to measure moisture, density, weight and other substances that correlate with these parameters.

Microwave is independent or compensated to environmental changes like temperature, humidity, vibrations, light etc. It has no aging or moving parts. It has long term stability. It has shown it can replace balances, density meters, beta ray heads, flow meters, thickness measurement systems and other indirect methods which are less accurate like 1-Parameter systems or light-based systems.

Learn More About Our Platform-Based OEM Solutions.

TEWS has more than 30 years of experience with microwave based moisture, density and mass related measurements. Other parameters being influenced by water or its absence or in conjunction with other parameters can also be detected.

TEWS offers a team of best-in-class-experts bringing in a wide range of knowledge such as engineers, physicists, mechanical designers and chemists.

Following our guideline of Co-Improving our customers`products, we offer a full range of services such as: analyzing the measurement task, making trial measurements, data sciences, modelling, adaptions of electronic and sensors - up to complete new developments.

Based on 4 electronic platforms from low to highspeed and different technologies as well as more than 100 different sensors we have the capability to realize new solutions for you within 12 months from kick-off to first prototype.

In terms of Co-Improving, this business development-process is closely co-ordinated with our clients. It includes all aspects, not only the technical part, but also with a strong emphasis on the cost-benefit calculation and the ROI for our customers.

How Can We Help You?