How our instruments can measure different tobacco blends, independent from its characteristics

- Cost savings

- Better quality

- Efficient processes

Our microwave works independently of the tobacco mass. For the work in the laboratory, this means that you no longer need the time-consuming weighing processes at the beginning and end of the conventional moisture determination with an oven. For the measurement, you simply fill our resonator via a funnel - this takes almost no time. The results are displayed immediately without destroying the sample. Even complete cigarettes including the paper can be measured directly.

Of course, our systems are also integrated into production machines to track density and moisture inline at speeds of up to 40,000 measurements per second.

However, the use of a microwave procedure depends essentially on the requirement for extensively sort independent, stable calibration when measuring moisture, to minimize the calibration workload as far as possible.

To prove this, TEWS made an examination for sort independent measurement of tobacco moisture, this examination included seven different finished blends from very dark to bright coloring, with semi-finished products such as stems or expanded tobacco, and more.

As a result, all tests indicated the essential sort independence of microwave calibration in spite of extreme changes in the blends and pre-blends, even with the addition of semi-finished products, saucing, casing, humectants, etc. in the normal concentrations will not have any essential effect on the calibration curve of the microwave unit.

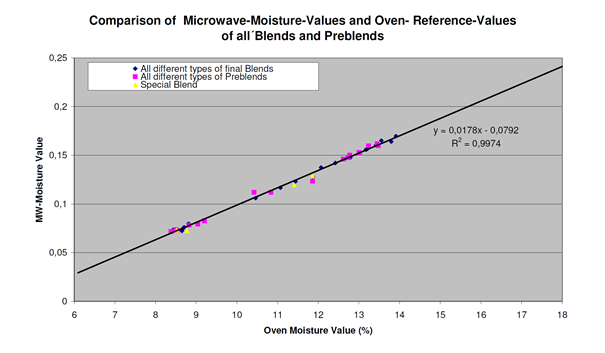

The following chart shows the outstanding relation between the moisture content of different types of final and pre-blends measured by the oven-reference and the microwave value of the TEWS instrument with a coefficient of determination as high as 0.9974.

All dots do not only represent one blend, pre-blend or special blend. Instead each dot represents several different blends – altogether there are even more than 20.

To cut a long story short: One linear calibration is sufficient for more than 20 different tobacco products covering a moisture range of 8% up to 14% giving you results instantaneously without switching articles.

This microwave technology is used in the entire tobacco process, from the incoming bale to the outgoing finished cigarette. For every location and need we have special solutions, all working with our patented microwave technology.

This will allow you to have a finish product with 100% quality control of the measured material in every step of your process. And the best thing, is that all of our systems are ready for industry 4.0, we offer AR Services as well as calibration support via our patented TCT – Cloud service.

If you are interested in the full report or if you need more information, please contact: Brian Hough, Tobacco Manager, +49 40 555 911-80, brian.hough@tewsworks.com