Microwave technology vs. KFT - which of the two is the more efficient technology?

Common measuring methods are for example loss-on-drying (using an oven or a halogen dryer) or NIR (Near Infrared spectroscopy).

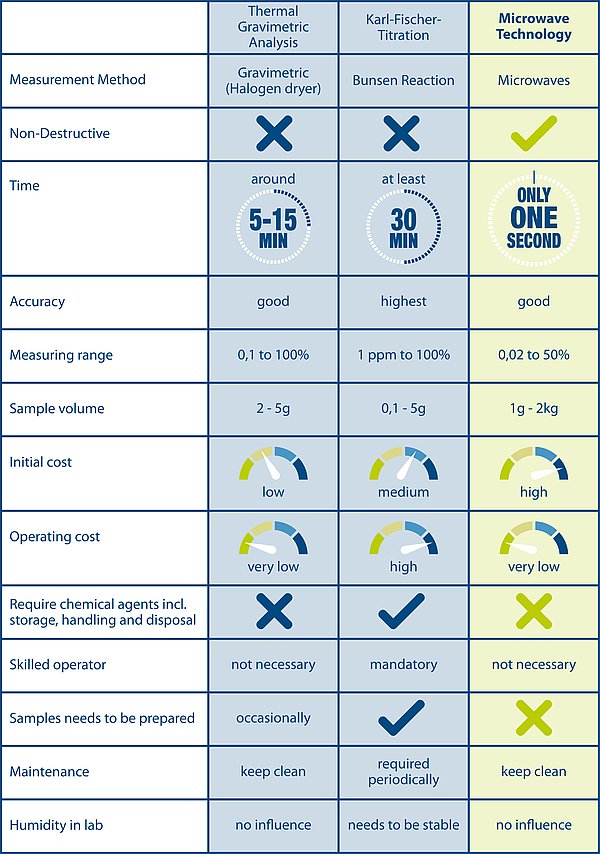

The Karl-Fischer Titration (KFT) is well known in the industry for providing the highest achievable measuring accuracy when it comes to moisture measurement – next to TEWS microwave technology. Still, it has several disadvantages that cannot be ignored.

KFT is a classic titration method in chemical analysis that uses coulometric or volumetric titration. This method detects only water, contrary to loss on drying, which detects any volatile substances. The technology was improved significantly over the last 85 years and there are a wide range of systems available to cover many different products. KFT is a destructive analysis and the sample quantity is small. Often the moisture inside a product is not homogeneously distributed and therefore it requires a thorough sample preparation which may include the use of grinders and mixers. To avoid mistakes during the measurement the operator needs to work very carefully and must avoid the influence of the humidity of the air. Different chemical agents are necessary for the measurement and they need to be stored in the lab and disposed after the measurement. So, one can say that the high measuring accuracy comes at a certain price. Only experienced personnel should operate the device and the cost of each measurement is in the range of €4 - €5.

However, there is a lesser known, but even better technology available in the market using microwaves (MW). It can be used for the moisture measurement of many different products like beans incl. coffee & cocoa beans, candy incl. gummy bears, nuts, cereals, dried herbs, fruits & spices, seeds & oilseeds, and all kinds of powders like starch, gluten etc..

The unique TEWS dual parameter methodology is based on the simultaneous measurement of both the product moisture and the density. The sensor generates a low-energy electro-magnetic field, which interacts with the water molecules inside the product sample. Therefore, it measures not only the surface but also the core moisture of products by penetrating the sample. TEWS sensors are installed in the lab, at-line and inline along conveyers, chutes, in hoppers, oscillating conveyers or inside augers.

Main advantages of Microwave technology compared to KFT:

- Speed (up to 40 000 measurements per second, result is available within 1 second)

- Non-destructive

- No sample preparation necessary

- No handling, storage and disposal of chemical agents

- User friendly (no skilled operator necessary)

- Provides the average of a much bigger sample amount

- Short ROI due to no extra cost / measurement

To find out how microwave technology can benefit your business and industry, contact Knut Szemjonneck for a detailed consultation!