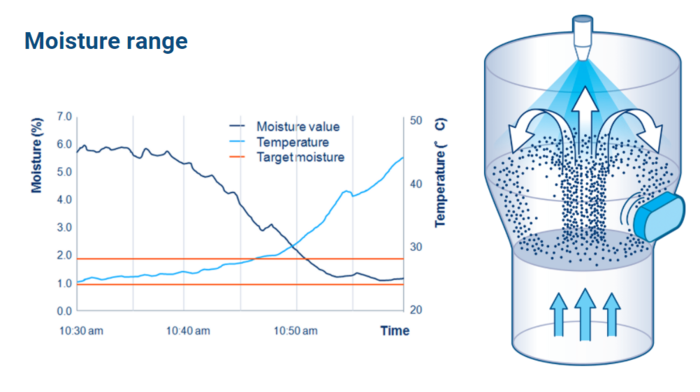

Fluid bed drying demands precise moisture control for optimal product quality and production efficiency. TEWS Solutions with its Microwave Technology revolutionizes this process by enabling continuous monitoring of moisture and particle size directly on the production line. This innovation eliminates operational interruptions, allowing for smoother processes and accurate endpoint detection, minimizing waste.

In the realm of continuous production, TEWS Solutions proves indispensable, ensuring seamless operations and maintaining stringent quality standards without traditional manual checks. Collaborating closely with OEM partners from the pharmaceutical industry, TEWS has developed a solution tailored to meet industry demands.

By integrating TEWS Solutions, companies can save significant costs and increase production capacity. A globally recognized customer reported EUR 50,000 in savings per FBD per annum, alongside a 6% capacity increase, translating to an extra 300 hours of production and EUR 90,000 in additional revenue annually. This underscores TEWS' pivotal role in shaping the future of fluid bed drying processes.

Benefits

Reduction of wasted batches.

100 % inline control for time savings

Automated determination of the end of the drying process

Increased annual productivity

ATEX for dust and gas available

IQ/OQ documentation

Operating software is in-line with 21 CFR Part 11 requirements

Main Advantages

MOISTURE & DENSITYIndependent measurement of moisture and bulk density and particle size in one step. | |

HIGH ACCURACYPenetration of particle / granule core, independent of color, surface, size, shape. | |

EASY TO OPERATEFree of wear and tear, low maintenance. Easy integration in the process. | |

HIGH SPEEDDirect measurements inside the fluid bed dryer, Real-time control of the batches. |

Return on investment*

12 months*according to our experience and estimation of costs with our partners. |