The safety and shelf life of pet food receives the same rigorous oversight as human food. With a diverse and expanding range of ingredients and formulas for cat and dog food, the importance of precise moisture measurement of dry pet food throughout the production process has become increasingly critical. This ensures that our beloved pets enjoy the highest standards of nutrition and safety in every bite.

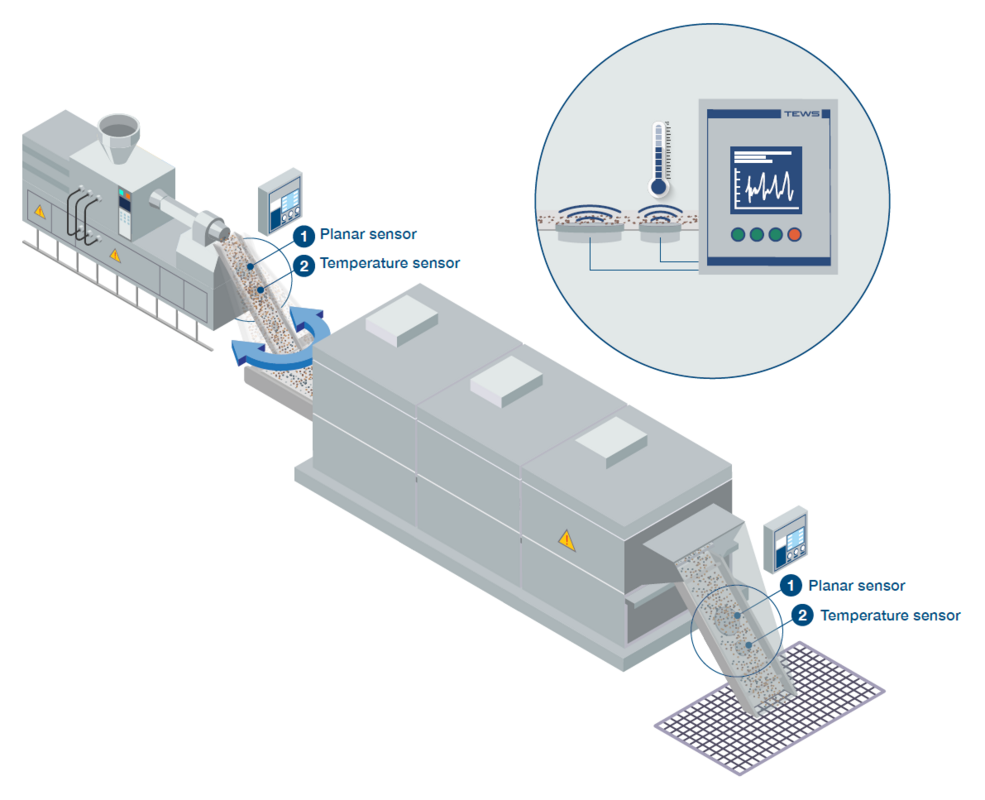

Just as with human food, the drying processes following extrusion are energy-intensive and require precise control. Ensuring inline bulk density and moisture measurement before and after the dryer is crucial to meeting requirements and optimizing cost efficiency. Microwave resonance technology stands out as a highly precise, reliable, and cost-effective method for this application. With a track record spanning decades and widespread integration into production lines worldwide, it offers unparalleled accuracy in maintaining quality standards while managing production costs effectively.

With TEWS, you gain the power to optimize your processes and ensure that your dry pet food maintains its highest quality, satisfying the discerning tastes of pet owners everywhere. Join us and learn how TEWS solutions can elevate your product and redefine what's possible in pet food quality and consistency to create a healthier future for our furry friends together.

Benefits

Achieve optimum moisture level for storage, pressing, conditioning, and extraction

100% quality control

High speed (up to 3.500)

Abrasion-proof and extra high-temperature sensors available

Energy savings during the drying process

CO2 emissions reduction

Main Advantages

MOISTURE & DENSITYIndependent measurement of moisture and bulk density and particle size in one step. | |

HIGH ACCURACYPenetration of product core independent of color, surface, size, shape. | |

EASY TO OPERATEFree of wear and tear, low maintenance. | |

HIGH-SPEEDDirect measurement during product flow, also under high-speed conditions. |

Return on Investment*

12 months*According to our experience and estimation of costs with our partners. |