Measurements That Secures Quality, Flavor & Compliance

Precision Moisture Control in Cacao Processing

In chocolate manufacturing, every detail matters—especially moisture content. From fermentation to drying and roasting, the moisture control in cacao beans and cacao nibs is essential to achieving premium quality, preventing spoilage, and complying with industry standards. A moisture content above 7.5% risks mold, fungus, and flavor loss—especially during long-term storage or export.

From Bean to Nib: Why Moisture Matters

Cacao beans are harvested, fermented, dried, and roasted to reduce moisture content to a safe level. These dried beans are then crushed into cacao nibs. This not only reduces residual moisture but also develops the complex flavor profile of chocolate. At this stage, moisture content must be precisely managed (lower than 7.5%) to ensure consistency and product safety.

Real-Time Insights with Moisture Sensors

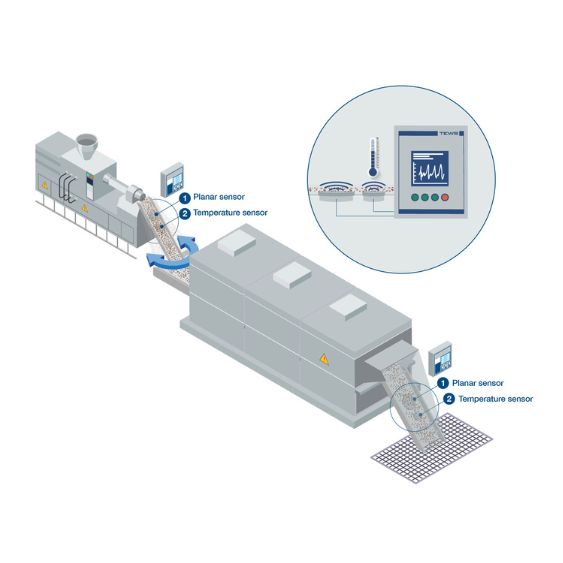

To ensure uniform quality across every batch, TEWS offers the microwave resonance technology for cacao, delivering real-time, non-destructive measurements directly in your production line or possibly in the lab as well. Whether you're measuring moisture in cacao nibs or monitoring the drying of beans, our system provides instant feedback to reduce waste, improve flavor development, and supporting compliance.

Trusted by Food Industry Leaders

With fast, accurate readings and easy integration, TEWS technology supports:

- Cacao nibs moisture measurement.

- Measurement of incoming goods.

- Moisture control during drying, roasting, and storage.

- Compliance with international cacao quality standards.

- Process optimization and energy savings.

Ready to Improve Your Cacao Process?

Get reliable, real-time data with TEWS’ patented moisture measurement solutions—trusted by manufacturers worldwide.

Get in touch today to optimize your roasting and drying lines with cutting-edge sensor technology.

Achieve real-time moisture level during drying, storage, or roasting.

100% quality control

Feedback for better compliance, faster decision-making, and streamlined process optimization.

Energy savings during the drying process

CO2 emissions reduction

MOISTURE & DENSITYIndependent measurement of moisture and bulk density and particle size in one step. | |

HIGH ACCURACYPenetration of product core independent of color, surface, size, shape. | |

EASY TO OPERATEFree of wear and tear, low maintenance. | |

HIGH-SPEEDDirect measurement during product flow, also under high-speed conditions. |

Explore the stories of our successful partners and envision your own path to success. Get inspired, take action, and create your own success story with TEWS solutions.

12 months*According to our experience and estimation of costs with our partners. |